E-pilot Joystick

A new joystick with 3 integrative axes for improved usability and to facilitate its installation in the tractor cabin.

A new joystick with 3 integrative axes for improved usability and to facilitate its installation in the tractor cabin.

MX is an agricultural equipment company, leader in France in the production of front loaders for plotters and second in Europe.

Industrial Designer

I worked with MX for 3 years, coordinating with engineers and technicians in the R&D office.

Solidworks, Cinema 4D, Octane, Keyshot, Adobe Photoshop, Rhino, Solid Edge, Autodesk Sketchbook.

CNC Machine, Foam, 3D printer, 3d scan.

A new joystick with 4 progressive axes.

Functionally, the design is simplistic. There is a micro-joystick on the top with a dual-axis for the thumb as well as two more axes at the base for the wrist. To improve ergonomics, I designed for the possibility to combined movements (lifting + dumping + 3rd function). These functional improvements allowed to finally be able to control all the axes from the front loader at the same time.

In response to a market for top-of-the-range tractors equipped with technical armrests, the aim was to design a joystick that was easy to integrate into the cabin without compromising on ergonomics to be able to work for many hours.

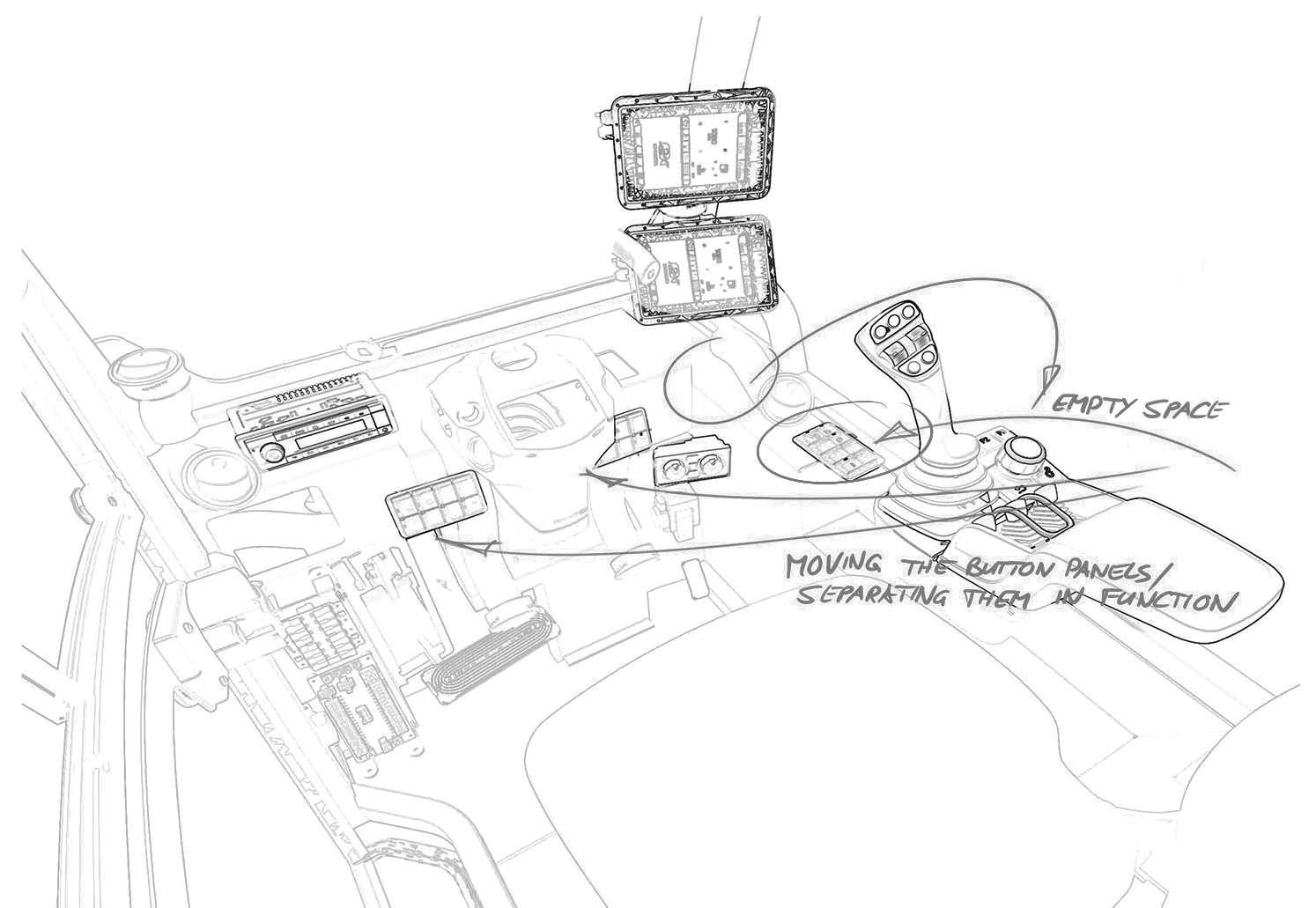

Due to the technical armrests, I studied every cabin interior. I then created a unique base to nimbly install the joystick to every empty space available.

The E-Pilot has been designed to control a front loader with 3 axes. With that aim in mind, the first step of the project was to define the best interactions to be able to combine the movements. The shape was also driven to provide a good area for grip, not to be disturbed by the shaking of the tractor.

To validate ergonomics and experiment with forms at every stage of the design process, I built early-on blue foam models and card prototypes.

Explorations of joystick interactions, control buttons, shapes.

Shape finding as a foundation

Simplified controls, being easily accessible

Support build around the product

When developing E-Pilot, it was important to quickly test the design. We applied a process of creating functional prototypes directly form the foam. Early-on I use blue foam models to generates ideas. The next step was creating the prototypes with a high density foam. This execution has allowed us to test many shapes in conditions controlling the front loader. After testing we could 3D scan the foam for refinement.