U400 Frontloader

Design of a new premium generation of front loaders that integrate all the elements inside a clean frame. The aim was to improve ergonomics without altering the manufacturing process.

Design of a new premium generation of front loaders that integrate all the elements inside a clean frame. The aim was to improve ergonomics without altering the manufacturing process.

MX is an agricultural equipment com- pany, leader in France in the production of front loaders for plotters and second in Europe.

Industrial Designer

I worked with MX for 3 years, coordinating with engineers and technicians in the R&D office.

Solidworks, Keyshot, Adobe Photoshop, Solid Edge.

A new generation of premium mid-range front loader.

The design process was driven from the beginning by the materials and processes. I worked with the engineers to understand the limits of the line of production. Following this process I was able to identify areas that could be shaped.

Additionally, We've updated the U400 series with new stands simply attached to the front loader and functionalities helping to make them one of the best on the market of middle range.

First proposals with design refinements

Final digital sketching of 400 series, The front loader has a dynamic appearance.

Using vanishing points help to focus on proportions, that give an aspect of stability to reflect robustness and quality.

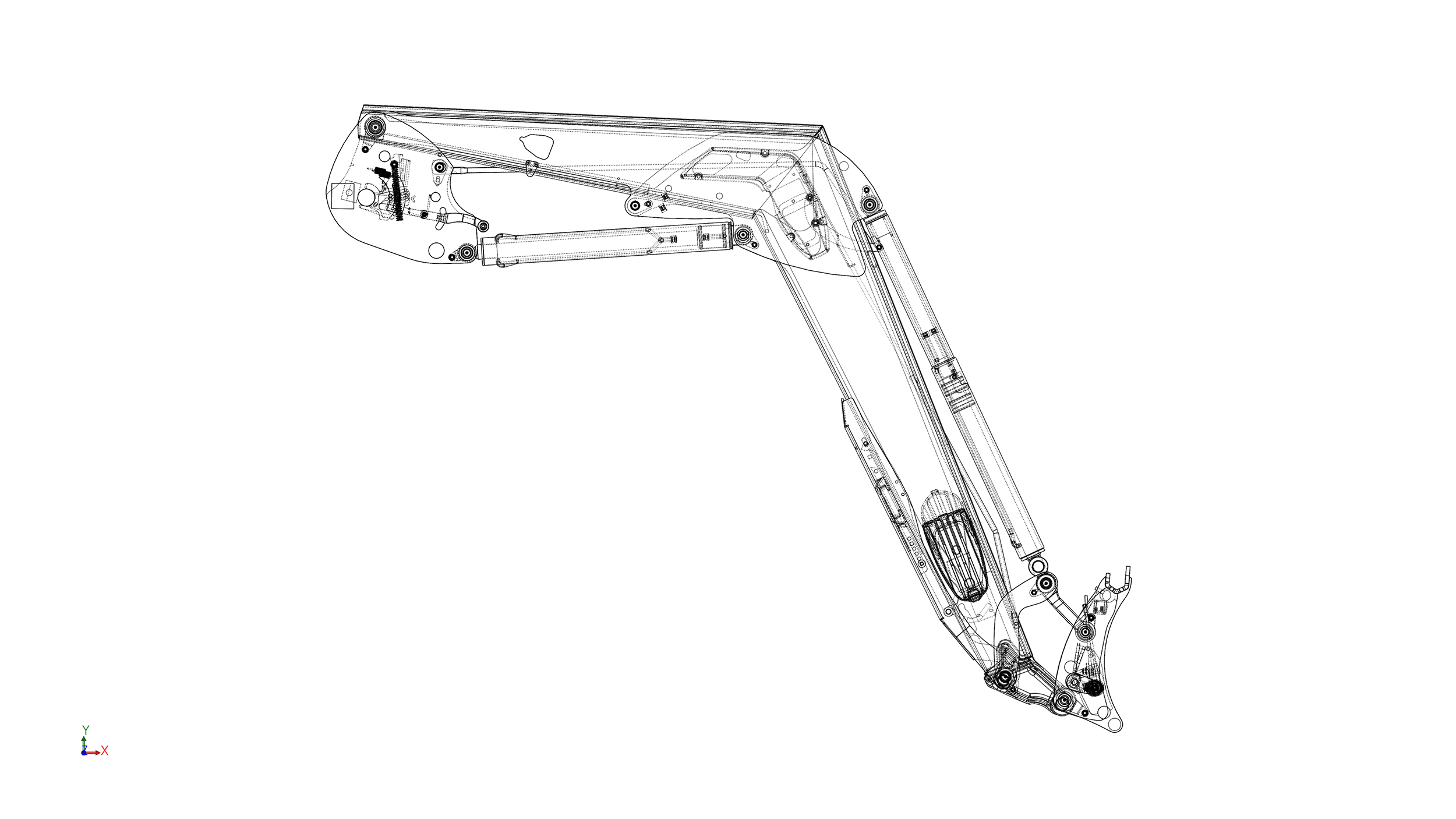

Following the process by starting the CAD by placing the components inside the frame. As well as adapting the design to the complete kinematics of the front loader.

The aim was to adapt every component into the frame for a clean aesthetic without compromising on the assembly.

As with all my work with MX, we created a range of full size prototypes during the design process to help us define and refine the final form, and assembly process.

Cutting optimization to reduce waste

Metal bending

Metal welding

Integrated cover protecting the crossbar

Dynamic edges converging at a single vanishing point

Visual marker for tilt angle

U400 Front-loaded in the production line

I designed the graphics and all edges of the product to converge at a single vanishing point for a dynamic and streamlined form.

Integrated stand with multiple angles of use